RADIATION DAMAGE RESEARCH

- Simulation of radiation environments

- Changes in semiconductors (integrated circuits)

- Chemical reaction enhancement

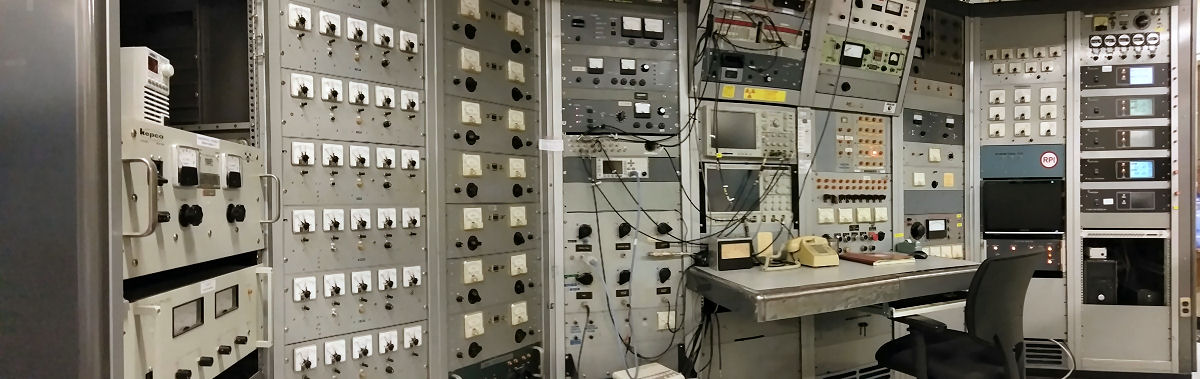

Just as heat can be very important for promoting many needed chemical and biological reactions and transformations, but is damaging when out of control, radiation also requires quantitative control based on a full understanding of its effects. The possible undesired effects of radiation must be understood both as a basis for determining proper doses, and for anticipating the results of irreducible background exposures under various operating conditions in the field or laboratory. Typical examples include effects on solid state electronics and biological systems. The LINAC provides opportunities for studying such effects under a wide range of levels of electron, gamma ray and neutron irradiation.

ELECTRONIC TESTING

- Operating characteristics of electronic systems

- Radiation qualification of electronic components

- Simulation of space and weapon environments

Ionizing radiation effects in semiconductors are encountered in nuclear power, space and defense electronics. Both high instantaneous dose rates and large integrated doses are required for testing. Both are provided by the RPI LINAC. Peak dose rates during short pulses of >1E11 rads per second and integrated dose rates in the megarad per second range can be obtained.

CRYSTAL COLOR ENHANCEMENT

In addition to the many applications of the accelerator, the use of radiation to produce color in topaz has been developed to a highly successful degree at the Gaerttner LINAC Center. Uncolored rough, preform or faceted topaz is subjected to the electron beam to form color centers in the material. The irradiation speeds up the natural process of coloration and results in gems with the much sought after sky blue or super blue color. Topaz that would normally be discarded becomes commercially and aesthetically desirable.

RADIATION CURING OF MATERIALS

Use of the maximum electron energy of the LINAC provides near optimum conditions for radiation curing including a full range of energy and ample space for irradiating large specimens. Examples of current applications of radiation cured polymers include crosslinked insulated wire, heat shrinkable tubing and packaging film, foam polyethylene, Teflon coated cookware, sheet rubber products, and advanced printing techniques (such as used on record jackets and metal and plastic containers) among others. Advantages over solvent-based thermal curing are elimination of hazardous solvents from the curing process, curing of thick sections, curing which takes place near or even below room temperature and very fast curing times, all with relatively low energy consumption.

NUCLEAR REACTIONS

The Gaerttner Center has been actively involved in research and development in neutron cross section measurements from the beginning of the laboratory. Many of the neutron cross sections required for reactor development have been measured at this laboratory. This experience, including extensive instrumentation and radiation detector development, can be applied directly to developing such areas as the production of accelerator generated radionuclides, activation of components (e.g. activating a component that will be used in a machine to measure wear and/or oil contamination, etc.), activation analysis using photons rather than neutrons, radionuclide identification through measurement of decay products, sensitive measurement of activation products (i.e. during sterilization or radurization processes) and numerous others. The combination of energetic electrons, photons, and neutrons generated by the LINAC provide many opportunities in nuclear reaction applications.

The high level of gamma radiation inside a nuclear reactor has important effects on structural materials, including those influenced by radiation effects on water chemistry. The LINAC, operating at full power, can produce the high radiation fields necessary for the study of these effects, and for the testing of diagnostic methods for reactor applications.

RADIOGRAPHY

Radiography utilizing advanced X-ray cameras and image processing systems is rapidly being applied to industrial non-destructive inspection and on-line manufacturing problems. The laboratory welcomes industrial R&Din radiography. At Rensselaer there are X-ray sources that range from 25 keV to 250 keV with hard tube generators to the multi-MeV intense bremsstrahlung source from the electron LINAC. Camera systems incorporating image intensifiers, fiber optic scintillator and phosphor sheets are available to match the needs of many inspection requirements, and new systems can be developed for specific applications. The LINAC has demonstrated supervoltage computed tomography, where the equivalent of the 4m diameter shuttle rocket has been successfully imaged with a spatial sensitivity of the order of one part per thousand (in thickness) and a density sensitivity of the order of a few percent.

STERILIZATION OF MEDICAL PRODUCTS

To sterilize is to make things free of microorganisms. Large doses of radiation will kill microorganisms and in recent years the medical industry has introduced radiation to sterilize medical products which do not lend themselves to sterilization by heat or steam. Particular interest has focused on plastic disposables such as syringes and blood transfusion sets, as well as complex apparatus such as heart-lung machines and kidney dialysis units. The Gaerttner LINAC Center can be of invaluable assistance to the producer of medical products which require sterilization and to the researcher in the medical sterilization field as this industry strives to develop and apply the process to its full potential.

FOOD PRESERVATION

The electron accelerator at the Gaerttner LINAC Center can be a useful tool in the development of improved food irradiation techniques. In the food irradiation process, a variety of fresh vegetables, seafood and meats are subjected to high energy electron beams to obtain various radiation treatments, depending on dose and complexity of the food. Irradiation can delay sprouting in root crops; kill insects in vegetables and stored grains; kill parasites in fresh meats and seafood; delay ripening and decay in fruits; and kill bacterial spores that cause trichinosis and botulism. All this can be accomplished without making the food radioactive.